We speak with Nathalie De Ridder, sales director, South West Europe, for DS Smith Plastics about the company’s relationship with Middle East dairy company Almarai, and its bag-in-box products.

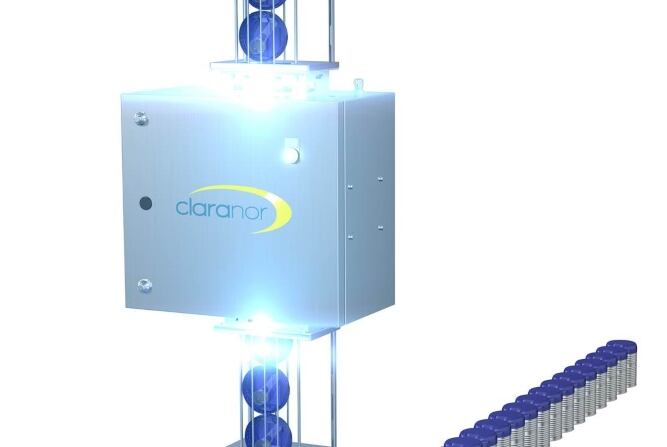

We also talk to Christophe Riedel, CEO of Claranor SA, about its Infant powder cans pulsed light sterilizer, which will be previewed at Pack-Expo in Chicago next week.

And SIG’s newly-installed solar energy roof at its Rayong, Thailand plant is the subject of our discussion with Klaus Zauner, who was plant manager when the installation was commissioned and completed.

DS Smith Plastics Rapak and Almarai Bag-in-Box in the Middle East

Since 2006 DS Smith Plastics Rapak has been a partner of Saudi Arabia-based Almarai, the biggest food and beverage manufacturing and distribution company in the Middle East.

The company chose DS Smith’s Bag-in-Box for its intermediate packaging for the region.

Rapak said its Bag-in-Box offered maximum product protection and an extended shelf life for dairy of up to 10 days after opening. A wide range of sizes – from 1.5 liter to 1,400 liter intermediate bulk containers – was another benefit in favor of this packaging format.

The Rapak team suggested its patented Intasept technology for the weather conditions in the Middle East. Intasept is the only aseptic filling system for flexible bags in the market that offers the security of heat-sealed closure before and after filling. The double membrane protection on Intasept bags ensures maximum safety for ambient dairy and for added active ingredients such as Omega 3, vitamins and minerals.

Rapak also designed a custom Intasept filling machine and special 10 liter, 20 liter and 1,100 liter irradiated bags with fitments for enhanced product safety.

In 2013, Parak introduced the next generation of 32mm Intasept gland with a new energy-rising technology, which ensured a more effective seal, enhancing the security and integrity of the technology. Additionally, the range of aseptic dispense fitments was expanded, enabling the technology to be used for an even wider variety of liquid products.

Market challenges

The dairy company said it ‘highly appreciates the benefits of Bag-in-Box that has become the main intermediate format for several products such as feta cheese and camel milk.’

DS Smith Rapak told DairyReporter the Middle East poses three specific challenges in packaging.

“Many rural areas are difficult to access and the transport conditions are harsh, requiring durable packaging that could stand the toll caused by these conditions. At Rapak, we are mostly supplying high barrier heavy duty Bag-in-Box packaging for this region to make sure the product gets to its final destination in perfect condition.”

Long distances also pose a challenge that requires packaging that assists in optimizing loads and reduces transportation costs.

“Bag-in-Box packaging is the ideal format for load optimization as it is stackable and perfectly square. Indeed, Bag-in-Box occupies 90% less space compared to traditional packaging such as bottles, thus reducing the cost and the number of trucks required.”

And the climate also has to be considered.

“Product wastage due to elevated temperatures makes products transported in this area to either require transport refrigeration or a packaging that can protect it from the heat and can keep it cooler for longer, such as Bag-in-Box,” DS Smith said.

Bag-in-Box also has sustainability features, the company said, as it carried out a ‘Lifecycle Analysis’ that shows the format provides environmental advantages over other alternatives.

Bag-in-Box is a more efficient option compared to any smaller packaging, giving an opportunity to have larger quantities with less plastic waste. The company said the 4 liter options saves 87% of the carbon footprint compared to HDPE bottles and 79% compared to pails, while the outer part of Bag-in-Box is 100% recyclable and contains approximately 88% recycled content.

Infant formula packaging sterilization

French company Claranor is introducing pulsed light technology for infant formula packaging sterilization.

To achieve the dry sterilization needed for the infant powdered formula packaging industry, a new cooling system by air has been designed instead of the water-cooling system currently used. The range of decontamination equipment is dedicated to the baby powder milk category: can, can end, cap with integrated spoon of all shapes, sizes or material can be instantaneously treated in line by pulsed light.

According to Claranor, pulsed light ensures a similar or higher packaging decontamination than conventional methods, and the microbiological decontamination is measurable and has been validated by an independent laboratory, the Fraunhofer Institute IVV.

The Claranor system also benefits from heat not being released in the environment around the conveyor, instead it is eliminated outside the production room.

The equipment is compact and can be integrated on a new or existing line, and running costs are lower, along with lower energy consumption.

The infant powder cans pulsed light sterilizer will be previewed at Pack-Expo in Chicago, October 14-17.

SIG solar in Thailand

German-based packaging company SIG has officially opened a solar roof on its facility in Rayong, Thailand, which the company says is the largest of its kind in the entire region.

According to its Power Development Plan, Thailand wants to cover 40% of its electricity requirements from renewable energy sources by 2036 - a goal SIG has already achieved. All SIG production plants worldwide are already powered by green electricity.

The Rayong packaging plant built its own photovoltaic system in cooperation with Symbior Solar.

Covering an area of 17,664 sqm, this solar project with 9,048 solar panels can produce up to 4,431 megawatt hours of electricity per year which in turn reduces CO2 emissions by up to 90%, whilst also saving electricity cost.